商品圖片僅供參考,選購時請再留意商品規格

商品圖片僅供參考,選購時請再留意商品規格

LIGHTMACHINERY IMPACT 2000系列CO2雷射器

商品包含多種型號及規格,請點選「立即選購規格」挑選

月結報帳 / 信用卡 / 銀行轉帳

宅配快速到貨,滿 NT$ 999 元即享免運!

選購型號

商品介紹

IMPACT-2000 Series short-pulse (TEA) CO2 lasers (originally developed by Lumonics Inc. and now offered by LightMachinery Inc.) are primarily designed for fineprocessing of non-metallic materials.

The Impact-2000 Series lasers are ideally suited for the selective removal or machining of non-metallic layers deposited on a metallic under-layer. Unlike conventional CO2 lasers, the short pulses and high peak powers of TEA CO2 lasers enable the surface layer to be removed (“ablated”) with little or no effect on the underlying metal substrate, and with minimal thermal damage (“heat-affectedzone” or “HAZ”) to the surrounding polymer material.

Typical applications include processing of medical device components (insulation stripping of fine electrical wires, leads and coils for implantable devices, drilling and coating removal of catheters and lead wires); microvia-drilling and insulation patterning / removal in printed and flexible circuits; “on-the-fly” drilling or patterning of controlled and rapid release pharmaceutical capsules and tablets; marking of security and anti-counterfeiting codes; laser ultrasound non-destructive testing. Feature sizes as low as ~50 μm can be achieved.

In these and other applications, IMPACT-2000 Series lasers can offer an extremely cost-effective alternative to excimer lasers, with faster throughput, simpler operation and lower cost-of-ownership.

Industrial CO2 lasers normally operate at an infrared wavelength of 10.6 μm. However, for most applications involving the processing of non-metallic / polymer materials, a wavelength in the 9 μm region usually provides superior processing quality. The Impact-2000 Series lasers can be set to operate at either wavelength, depending on the specific application.

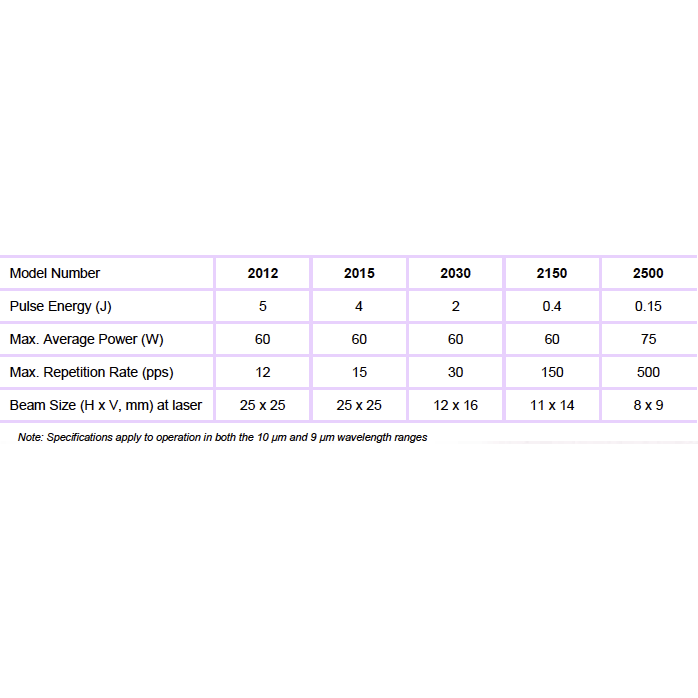

Various models of the Impact-2000 Series lasers are available, offering a choice of pulse energy and repetition rates. LightMachinery will be happy to process your samples in our Applications Laboratory and to recommend the particular model and configuration of IMPACT-2000 Series laser best suited for your application.

FEATURE

Megawatt peak powers give excellent edge-definition in non-metallic materials

Greatly reduced heat-affected-zone (HAZ) compared to conventional CO2 lasers

A cost-effective alternative to excimer lasers for many processes

RELATED APPLICATIONS

Drilling, patterning and ablation of non-metallic materials

Selective removal of polymer materials from a metal substrate with no damage to the metallic backing

Wire stripping

Medical device components

Drilling of controlled-release and rapid-release pharmaceutical tablets and capsules

Microvia-hole drilling in printed circuits

Flex-circuit processing

Laser ultrasound non-destructive testing

以上圖片及相關資訊由 LIGHTMACHINERY提供。

若有現場安裝、說明或特殊配送需求,歡迎事前與科研市集聯繫。部分商品因供應條件限制,可能無法提供相關服務,敬請見諒。